Function

Deep Well Turbine Pumps are basically centrifugal pumps which are used for high heads, high efficiency and constant flow rates. The pump bowl assembly is submerged in the fluid to be pumped. Deep Well Turbine Pumps push the fluid to the surface through a column pipe and then through a head assembly. Vertical line-shaft pumps with submerged pump bowl assembly, line-shaft and the drive unit on the surface are suitable for installation in deep

wells and tanks. Featuring an extremely solid and reliable construction design, these pumps ensure great application flexibility. The pump bowl assembly which may be a single stage or multi-stage (according to the system head efficiency requirement), is rapidly split and the intermediate bowls are interchangeable. Increase or decrease in the number of bowls changes the head efficiency of the pump. Deep Well Turbine Pumps are single/multistage pumps operating in the vertical position.

Although their construction and operational features have undergone a continuous evolution over the years, yet their basic operational principle remained the same. Produced liquids, after being subjected to great centrifugal forces caused by high rotational inertia of the impellers, lose their kinetic energy in the diffuser where a conversion of kinetic energy to pressure energy takes place. This is the main operational mechanism of the radial and mixed flow

pumps. The pump shaft is connected to a vertical hollow shaft motor through line-shafts enclosed within the column pipes. Water enters the pump through intake side and is lifted up by the pump bowl assembly.

Construction

This pump consists of three main parts i.e. Bowl Assembly, Column Pipes and Shaft Assembly, and the Discharge Head. Bowl assembly is in grey cast iron and specially designed dynamically balanced impellers are in bronze. Column pipes are in mild steel and column shafts are in carbon steel. Top shaft and

pump shaft used are made of stainless steel SAE 304 for more reliable and durable pump operation. Discharge head is in grey cast iron. GOLDEN Hollow-Shaft Vertical Motors with 4 poles (1450 rpm) are suitable for these kind of pumps. GOLDEN Vertical Hollow Shaft Motors include the range 10 HP, 15 HP, 20 HP, 25 HP, 30 HP, 40 HP.

Application

These types of pumps are suitable for water supply in Housing Societies / Municipalities for Over-Head Tanks, Irrigation, Construction Sites, in Commercial buildings, also for Agricultural and Industrial sector.

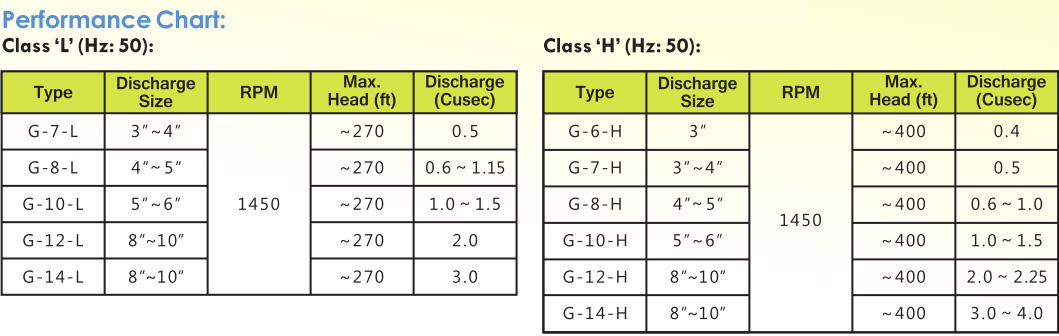

Pump Performance Data

Max. Capacity : 4.0 Cusec (max.)

Max. Head : 80 m (max.)

Speed : 1450 rpm

Max. Outlet: 10″

The pump liquid has to be chemically and mechanically suitable and compatible for the pump material.

Max. Temp. of pumped liquids : -15°C to +70°C

Max. Ambient Temp. : 40°C

Max. Working Presssure : 8 bar (max.)

Installation

The Deep Well Turbine Pumps can only be positioned in the vertical orientation and hence the motor direction is also vertical. These pumps can be operated both with Electric Hollow Shaft Motors and Golden Diesel Engines and they ensure unequalled service efficiency.

Related products

Golden Submersible Drainage Pumps

₨ 20,000 – ₨ 275,000Price range: ₨ 20,000 through ₨ 275,000Add to Cart This product has multiple variants. The options may be chosen on the product pageGOLDEN Submersible Sewage Pumps

₨ 114,000 – ₨ 156,000Price range: ₨ 114,000 through ₨ 156,000Add to Cart This product has multiple variants. The options may be chosen on the product pageGolden Submersible Pumps GSP 6 – Series

₨ 240,000 – ₨ 336,000Price range: ₨ 240,000 through ₨ 336,000Add to Cart This product has multiple variants. The options may be chosen on the product pageGolden Mobile Trolley Set

Add to Cart This product has multiple variants. The options may be chosen on the product page

Follow Us On Facebook

Office Hours

Mon-Thu: 8:00-16:30

Fri: Closed

Sat-Sun: 8:00-16:30

Golden Pumps Head Office

GOLDEN PUMPS (PVT) LTD.

Climax Town, Pindi Bypass,

G. T. Road, Gujranwala –

PAKISTAN

Tel: +92-55-3857621, 3857622

UAN: 111-GOLDEN (465-336)

E-mail: info@goldenpumps.com.pk

Web: www.goldenpumps.com.pk